Laser Engraving, Cleaning, Welding and Marking Machines

Get a quote

Products

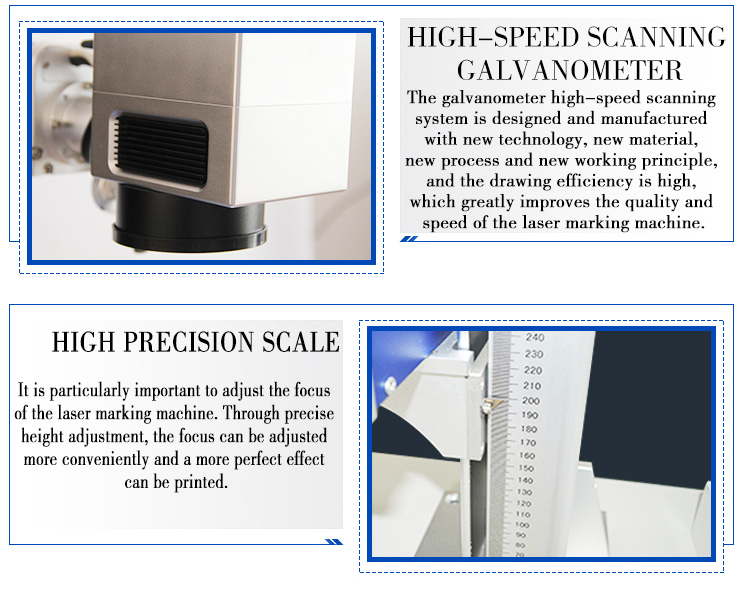

professional fiber laser marking machine for metal

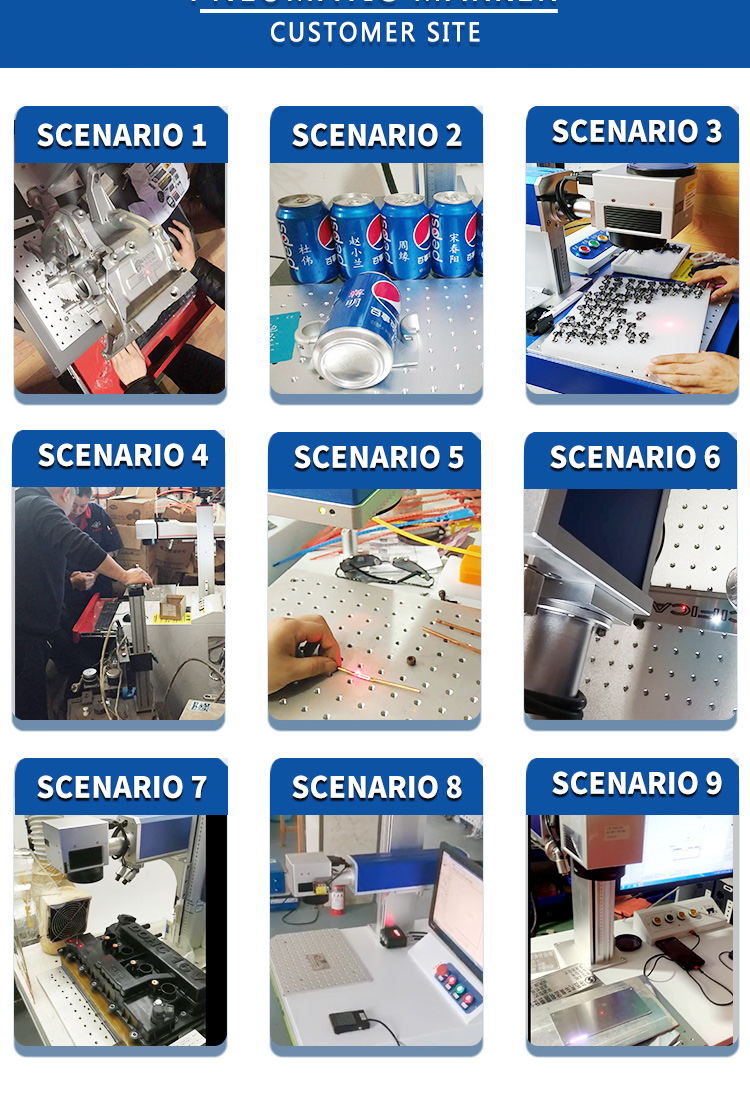

As manufacturing becomes more advanced, businesses continue to seek faster and more efficient ways to mark products. A very effective method is to use a professional fiber laser marking machine designed for metal materials.

Unlike traditional marking methods such as engraving, stamping or printing, fiber laser machines use high-power lasers to alter the surface of the metal material being marked. These machines are so precise that they can make intricate and detailed marks on almost any type of metal, including steel, aluminum, copper and brass.

Professional fiber laser marking machines use a concentrated beam of light to create a high-quality mark on metal surfaces that is both permanent and durable. The technology is so precise that there is no room for error, making it a popular choice in industries as diverse as jewelry manufacturing, aerospace, automotive and medical device manufacturing.

Fiber lasers can produce marks of varying depths and widths, depending on the setup used, and can produce marks as small as a few microns. Additionally, fiber laser machines can be used to mark logos, serial numbers, bar codes and various other types of text and graphics.

One of the advantages of using a professional metal fiber laser marking machine is the speed and efficiency of the process. Laser marking is much faster and produces consistent results than traditional marking methods. Over time, this can lead to increased productivity and significant cost savings.

Another advantage of using a fiber laser marking machine is that the markings are very precise and durable. These machines produce high quality markings that are resistant to abrasion, corrosion and UV rays. They are also less likely to fade, stain or scratch, making them ideal for applications that require durability.