Laser Engraving, Cleaning, Welding and Marking Machines

Get a quote

Products

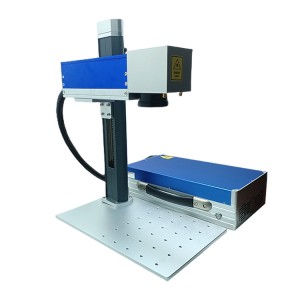

Portable fiber laser marking machine 50w

Marking machinery has become an essential tool for industries around the world, particularly for those that work with metal and plastic materials.

Two of the most commonly used machines in the industry are the dot peen marking machine and the pneumatic marking machine.

Both of these machines are known for their ability to mark materials with precision and accuracy. In this article, we will be discussing the differences between these two machines and why a light weight version is beneficial for businesses.

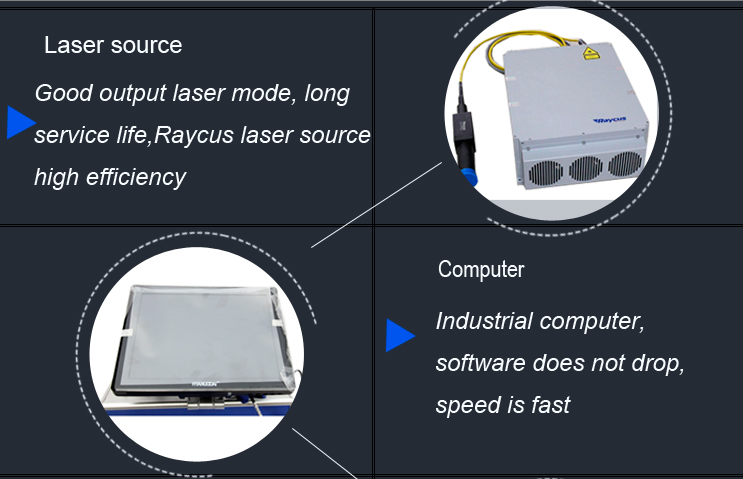

First, the 50W portable fiber laser marking machine is capable of marking various materials with high precision and high speed. From metals such as stainless steel, aluminum, and copper, to plastics, ceramics, and even wood and leather, the machine provides a versatile marking solution for businesses in a variety of industries.

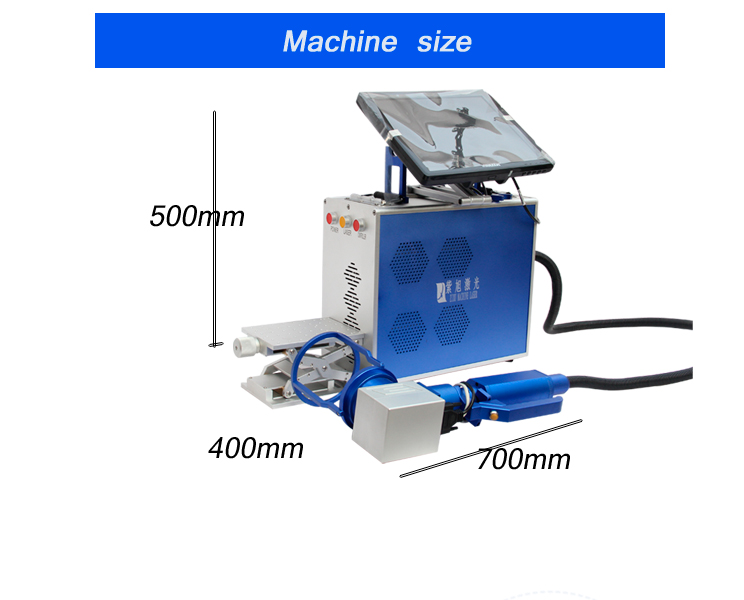

Second, the machine's portability makes it ideal for businesses with limited space or those that need to move their marking operations from one location to another. These machines fit easily on a table or tabletop, making them ideal for small workshops, laboratories, or even out in the field.

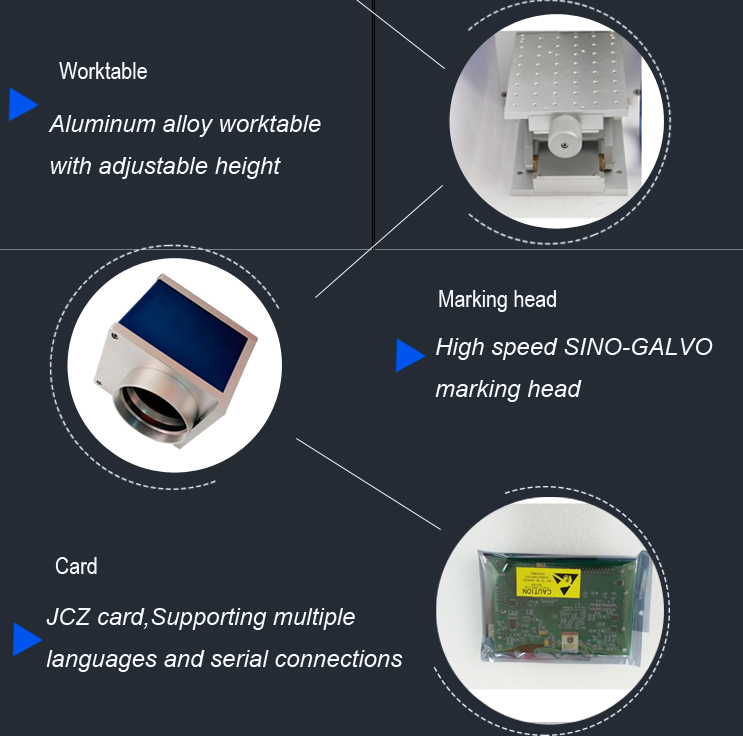

In addition, the 50W portable fiber laser marking machine can be highly customized for different marking needs. Its software can create a variety of marks, including text, graphics, barcodes and logos, among others. The machine's laser beam can also be adjusted to accommodate different materials, marking depths and line widths, ensuring the best marking results every time.

In addition, the 50W portable fiber laser marking machine provides a fast and efficient marking solution that can help businesses save time and money. It can mark a large number of parts per hour, ensuring high throughput and productivity. Plus, it has extremely low maintenance requirements, making it a cost-effective investment for businesses.

Finally, the 50W portable fiber laser marking machine is very environmentally friendly, with low operating costs and no excess waste or pollution. It requires no consumables or ink, and its marking process leaves a clean, permanent mark that requires no post-processing.