Introduction:In recent years, the use of handheld laser welding machines has become increasingly popular in various industries. These machines offer precision and versatility, making them an essential tool for welding professionals. This article will guide you on how to effectively use a handheld laser welding machine.

Safety Precautions:Before operating the handheld laser welding machine, it is crucial to prioritize safety. Wear appropriate protective gear such as safety glasses, gloves, and a welding apron. Ensure that the work area is well-ventilated and clear of any flammable materials. It is also essential to read and understand the manufacturer’s instructions and safety guidelines before usage.

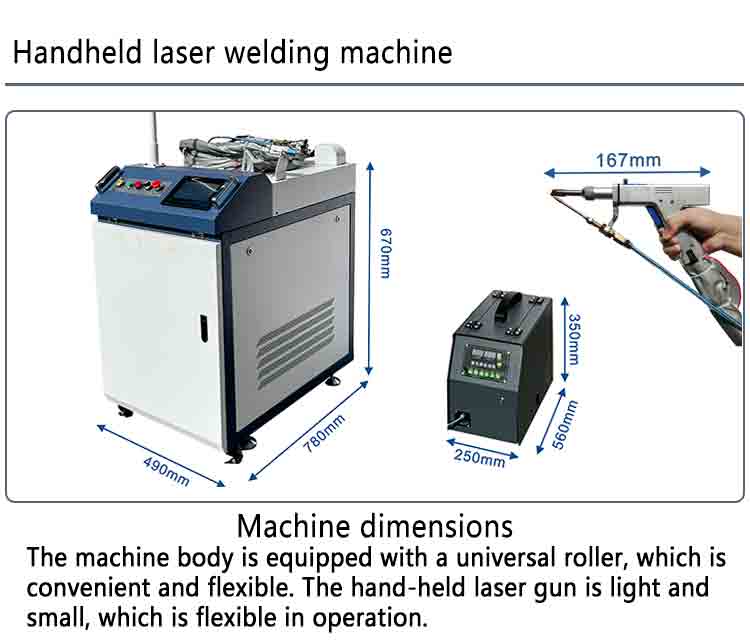

Machine Setup:Start by selecting the appropriate welding parameters such as laser power, pulse frequency, and welding speed based on the material and thickness being welded. Refer to the machine manual or consult with an expert if necessary. Connect the machine to a reliable power source and ensure all connections are secure. Begin by testing the machine on a sample piece to ensure it is functioning correctly.

Material Preparation:Prepare the materials to be welded by cleaning and removing any dirt, grease, or rust. Ensure that the joint edges are smooth and properly aligned. Use appropriate clamps or fixtures to hold the materials securely in place to avoid any movement during the welding process. Position the materials in a way that provides clear access for the laser beam.

Laser Welding Technique:Hold the handheld laser welding machine firmly with both hands and position it at an appropriate distance from the joint. Align the laser beam with the joint line and activate the laser. Move the machine steadily along the joint, maintaining a consistent speed to ensure a uniform weld. Keep the laser beam focused on the joint, ensuring it does not deviate from the desired welding path. Adjust the movement speed to achieve the desired penetration depth and bead appearance.

Weld Quality and Inspection:Inspect the weld after each pass to ensure the desired weld quality. Pay attention to the weld bead’s shape, penetration depth, and absence of any porosity or cracks. Adjust the welding parameters if necessary to achieve the desired results. Use non-destructive testing methods such as dye penetrant or visual inspection to identify any defects in the weld. If defects are found, analyze the welding parameters and make appropriate adjustments for subsequent welds.

Post-welding Steps:Once the welding process is complete, allow the weld to cool down naturally. Use appropriate cooling methods if required. Remove any slag or spatter using a wire brush or appropriate cleaning tools. Assess the overall quality of the weld and make any necessary repairs or modifications. Remember to power off the machine and disconnect it from the power source before storing it.

Conclusion:By following these guidelines, you can effectively utilize a handheld laser welding machine. Prioritizing safety, proper machine setup, material preparation, and employing the correct welding technique will ensure high-quality welds. With practice and experience, you can master the art of using a handheld laser welding machine and achieve precise, reliable, and aesthetically pleasing welds in various applications.

Post time: Aug-28-2023