Portable pneumatic marking machine is an industrial marking equipment that is easy to carry and use. It uses a pneumatic drive system to generate the power required for marking, and is generally suitable for situations where marking needs to be done at industrial production sites. Below is an introduction to the device.

First of all, the main components of the carbon dioxide laser marking machine include the laser generator, scanning system, control system and workbench. The laser generator generates a high-energy CO2 laser beam. The scanning system is used to control the position and movement trajectory of the laser beam. The control system is used to control the operation and parameter settings of the entire marking machine. The workbench is used to place and fix the required Material for marking or cutting.

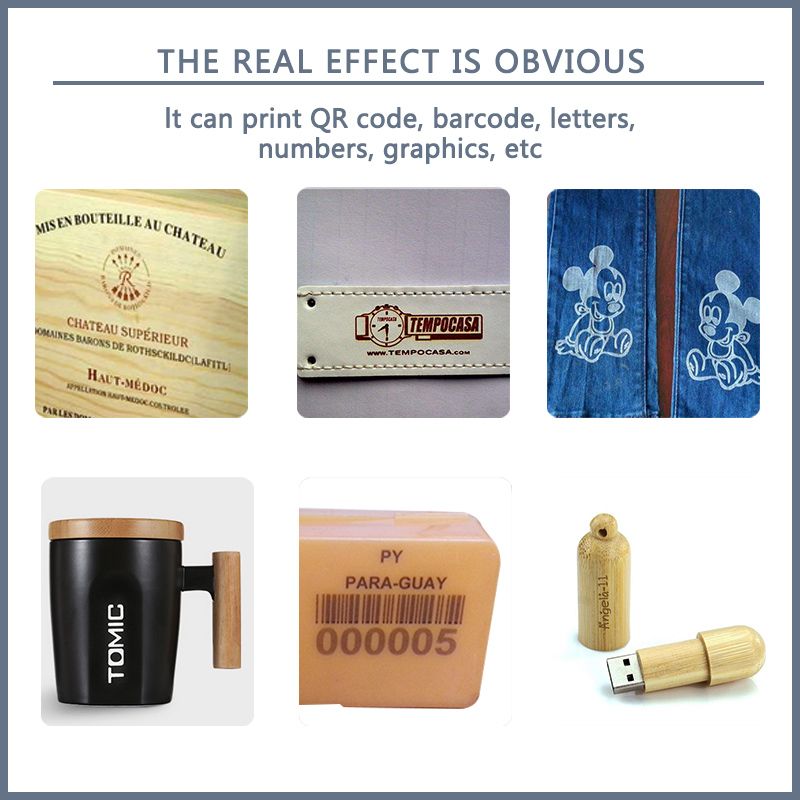

Secondly, carbon dioxide laser marking machines have many advantages. First of all, it can achieve non-contact processing, avoiding mechanical wear and deformation problems that may occur in traditional processing methods, thereby ensuring processing precision and finished product quality. Secondly, the carbon dioxide laser marking machine has high speed and efficiency and can complete a large number of processing tasks in a short time. In addition, it can also process complex patterns and fonts to meet various personalized needs. Moreover, the carbon dioxide laser marking machine has good applicability for different types of materials and can be suitable for processing various materials such as metal, plastic, rubber, ceramics, and glass.

To summarize, carbon dioxide laser marking machines have become one of the indispensable equipment in modern manufacturing due to their high efficiency, high precision and flexible processing capabilities. With the development and application of a series of new materials, the application fields of carbon dioxide laser marking machines will continue to expand, providing more possibilities for industrial production.

Post time: Feb-23-2024