Laser Engraving, Cleaning, Welding and Marking Machines

Get a quote

Products

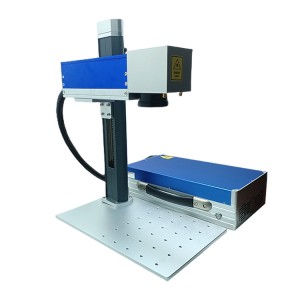

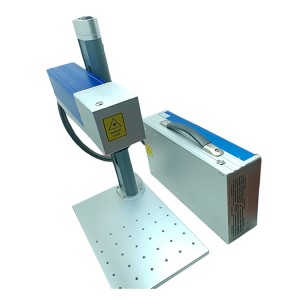

Laser marking machine for metal and non metal

A laser marking machine is a versatile and powerful piece of equipment that uses a laser to etch or engrave text, logos, images and designs on a variety of materials. These machines can be used on both metallic and non-metallic materials, providing flexibility in the marking process.

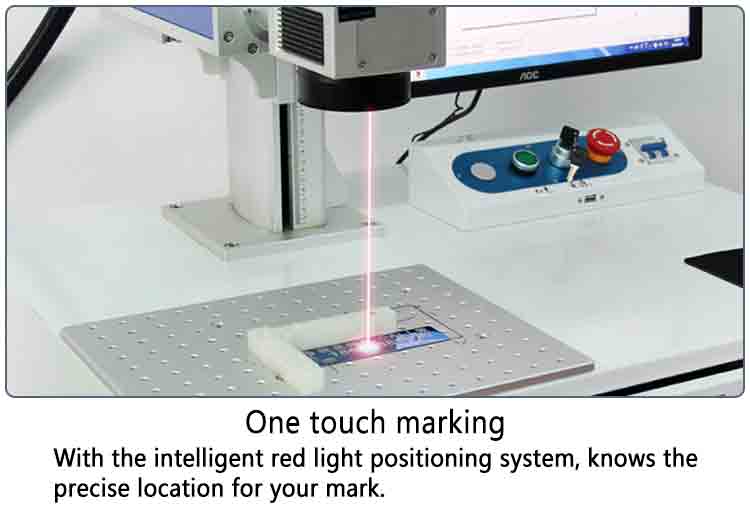

One of the main advantages of using a laser marking machine is the precision and accuracy of marking. Unlike traditional engraving methods such as hand engraving or mechanical engraving, laser marking machines can produce very fine, intricate details with a high degree of consistency and repeatability. This means businesses can create high-quality marks for branding or identification purposes, guaranteed to be accurate every time.

Another advantage of laser marking machines is their versatility. These machines can be used on a variety of metals, including steel, aluminum, and brass, as well as non-metallic materials such as plastics, ceramics, and even wood. The ability to mark a variety of materials makes laser marking machines an essential tool in many industries, from manufacturing to jewelry making.

Plus, laser marking machines are incredibly fast and efficient. They can quickly and accurately mark large quantities of products without causing any damage to the material. This means businesses can meet demanding orders and deadlines without sacrificing quality or accuracy.

A feature of laser marking machines is their ability to produce high-contrast marks. By adjusting the intensity of the laser beam, operators can create marks that are easy to read and distinguishable from the material itself. This is especially useful for identifying products or creating distinctive logos and branding.

Laser marking machines are also a cost-effective solution for businesses. Unlike traditional engraving methods, no consumables such as ink or replacement parts are required. The laser technology used in these machines is also energy efficient, which means lower operating costs over time.

Another advantage of laser marking machines is their environmental friendliness. Compared to other marking methods such as chemical etching or screen printing, laser marking is a cleaner and safer option because it produces no waste or pollution.

Finally, laser marking machines are programmable and can be easily integrated into existing manufacturing processes, including assembly lines. This means businesses can streamline production, increase accuracy and efficiency, and reduce errors and waste.

In short, laser marking machines provide enterprises with a precise, versatile and cost-effective product marking solution. They provide consistent and high-quality marking, can be used on a variety of materials, and are safe and environmentally friendly. Laser marking machines are essential tools in many industries, from heavy manufacturing to small handicrafts.

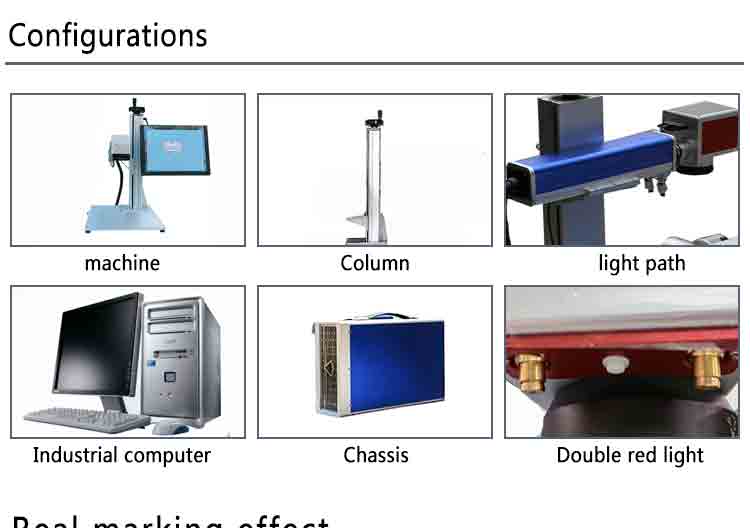

Our marking machine factory is a professional manufacturing environment that specializes in the design and production of marking machines. our factories use advanced technology to manufacture high-quality, scalable machines for customers.