Laser Engraving, Cleaning, Welding and Marking Machines

Get a quote

Products

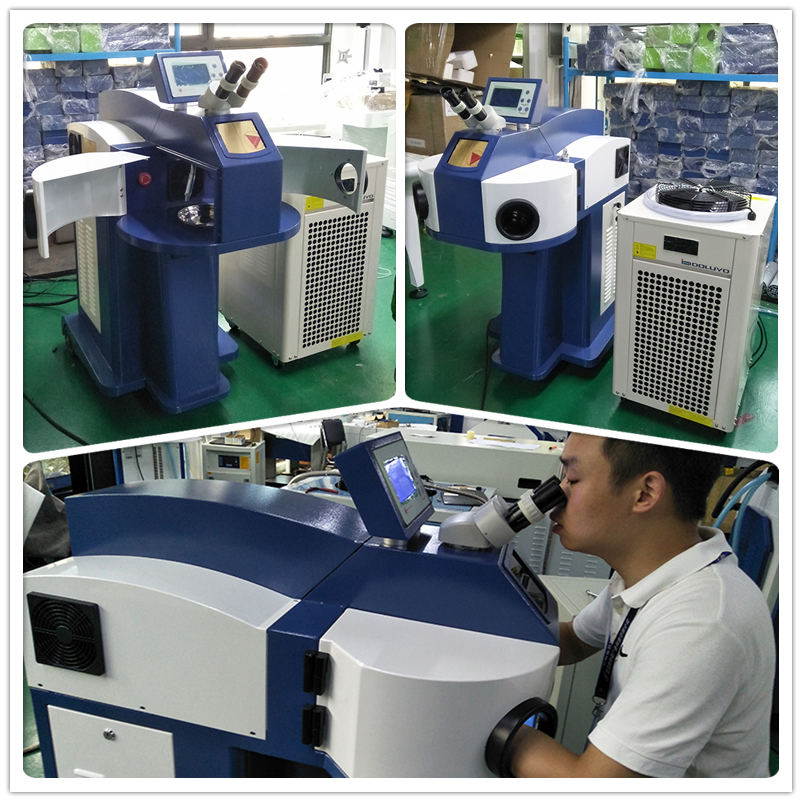

High Quality 200W Gold Jewelry Laser Welding Machine For Stainless Steel Gold And Silver Welding

Product Description

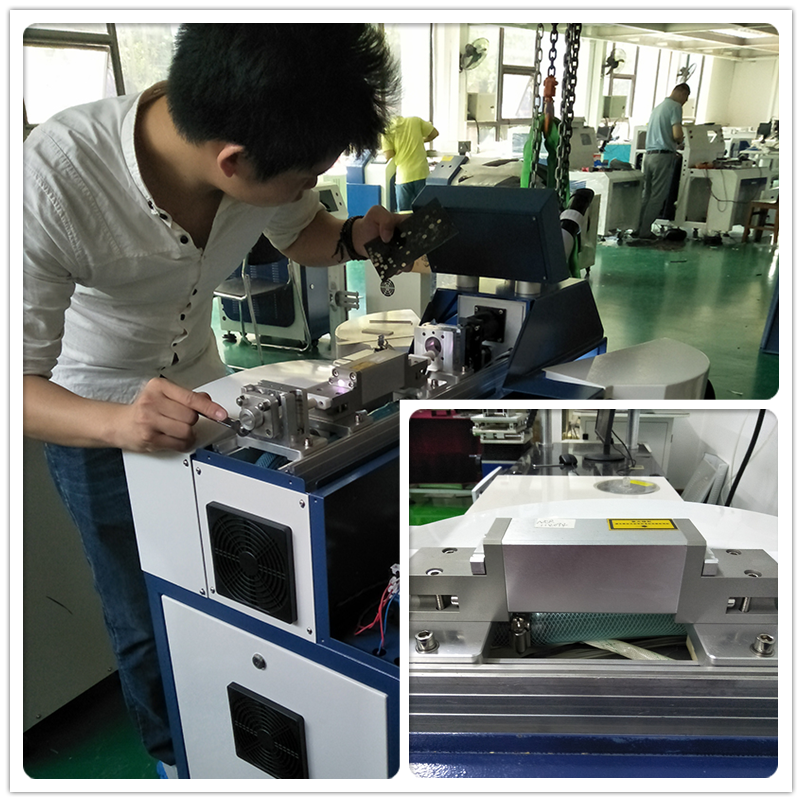

CHUKE Jewelry Laser Spot Welding Machine Tools For Jewellery is an important and basic aspect of laser welding technology. When laser radiation heats the surface of work-piece, the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool. Because of this unique feature, it is widely used in processing of precious jewelry or welding of precision parts

Advantage

· The laser head can rotate in multiple angles and directions, which is convenient for laser processing and positioning;

· The diameter of solder joint is small, the heat affected area is small, and the small and fine geometric area can be welded;

· There is no air hole and sand hole. After welding, grinding, polishing and skin wrinkle treatment can be carried out directly;

· No deformation and collapse of base material structure, no strength reduction and cracking after welding.

Technical Parameter

|

Power(W) |

200W |

|

Max laser output power |

200W |

|

Pulse frequency |

0.1-40Hz |

|

Voltage |

220VAC//50Hz/30A 380VAC/50Hz/40A |

|

Worktable range |

170*170mm |

|

Water pressure protection |

≤0.025MPa |

|

Dimension |

550*800*800(mm) |

|

Laser wavelength |

1064nm |

|

Holistic power |

6KW |

|

Pulse width |

0.1-20MS |

|

Cooling water temperature |

≤35 water temperature protection 45 |

|

Positional accuracy |

0.02mm |

|

Cooling put |

1.0p |

Applicable Industries

Jewelry Laser Spot Welding Machine Tools For Jewellery is used in aviation, aerospace, sports products, jewelry, golf head, medical instrument, titanium alloy denture, instrument, electronics, machinery, automobile, etc,especially for the perforating of gold and silver jewelry, spot welding, repairing, inlay and welding of claw.

CHUKE is a professional automatic laser marking engraving and cutting machine manufacturer in China. Our products include the fiber laser marking machine, laser marking machine, laser welding machine, laser engraving and cutting machine and so on, which have passed CE certification. Our machines are widely used for the arts and crafts, the machine parts, hardware tools, advertising sign, shipbuilding industry, auto parts, rubber molds, high-end machine tool, tire mold, Environmental protection industry and so on. We have many customers from different countries around the world.

--17 years of experience in the production and development of cnc laser coding equipment:

--Directly sales from factory to buyer;

--24 hours online after-sales.

If you need more customized requirements, please contact us: cqchuke@gmail.com