Laser Engraving, Cleaning, Welding and Marking Machines

Get a quote

Products

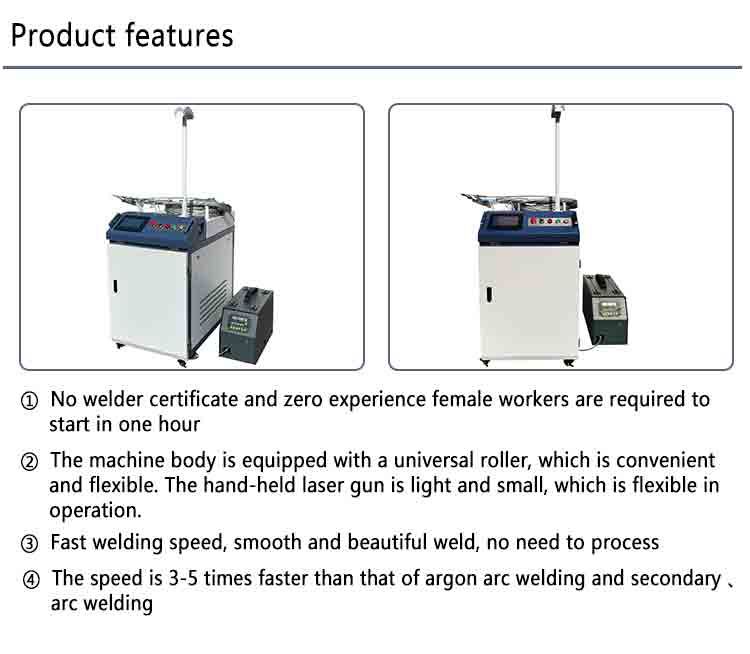

Fiber Laser Welding Machine

In recent years, fiber laser welding machines have emerged as a major technological advancement in the welding field. Fiber laser welding machines are revolutionizing the welding industry with their superior precision, efficiency and versatility. This article aims to show the main features and advantages of fiber laser welding machines.

Excellent precision: One of the main advantages of fiber laser welding machines is their exceptional precision. These machines use a high powered laser beam to create narrow and deep welds with minimal heat input. A focused laser beam allows precise control of the welding process, resulting in high-quality welds with minimal distortion. This precision is especially important in industries that require complex soldering, such as electronics, automotive and aerospace.

Improve efficiency: Fiber laser welding machines are known for their exceptional efficiency. These machines utilize fiber optic technology to deliver laser beams, ensuring a steady and focused source of energy. This enables faster welding speeds while maintaining precise control over the welding process. The ability to weld at higher speeds significantly increases productivity and reduces overall production costs. Additionally, minimal heat input and precise control of the laser beam minimizes the need for post-weld processing, further increasing efficiency.

Versatility: Another major advantage of fiber laser welding machines is their versatility. They are capable of welding a wide variety of materials, including stainless steel, aluminum, copper, and even dissimilar metals. Whether thin or thick materials, fiber laser welding machines provide consistent and reliable welds. Additionally, these machines can be used in a variety of welding applications, from sheet metal fabrication to assembly line production, making them suitable for different industries and applications.

Improved safety and environmental impact: Fiber laser welding machines have enhanced safety features compared to traditional welding methods. Because they use a focused laser beam, the risk of exposure to harmful fumes and radiation is significantly reduced. In addition, the minimal emissions of harmful gases and reduced power consumption contribute to a safer and greener work environment.

in conclusion: Fiber laser welding machines have revolutionized the welding industry by offering superior precision, greater efficiency, versatility, and increased safety. These machines have become essential tools in various industries, helping to produce high-quality welds while increasing productivity and reducing costs. As technology continues to advance, fiber laser welding machines will undoubtedly play a vital role in shaping the future of the welding industry.