Laser Engraving, Cleaning, Welding and Marking Machines

Get a quote

Products

fiber laser marking machine metal marking

In recent years, fiber laser marking machines have gained popularity due to their ability to mark a variety of materials with high precision and high speed. Among these materials, metals are one of the most commonly marked substrates. Fiber lasers are ideal for making durable and precise marks on a variety of metals including stainless steel, aluminum, titanium, brass and more.

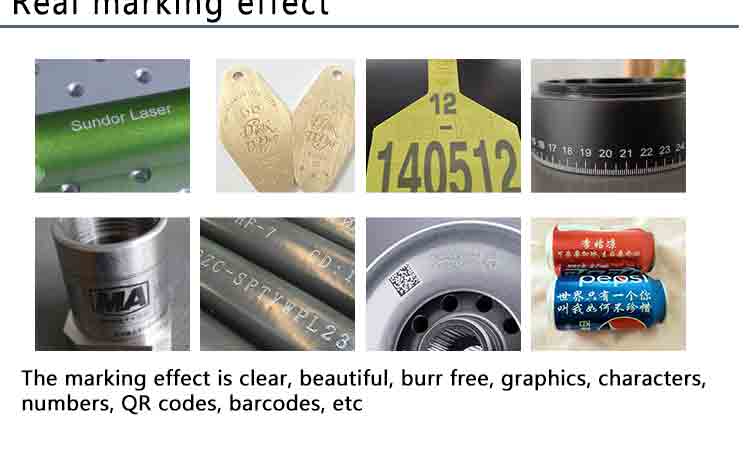

One of the main advantages of using a fiber laser marking machine for metal marking is its ability to provide high-contrast marking results. The laser beam creates detailed and sharp marks by removing thin layers of the metal surface. Unlike traditional marking methods such as engraving or etching, which can leave burrs, fiber laser marking produces smooth and clean results.

Fiber laser marking is also highly versatile when it comes to marking different types of metal surfaces. The intensity and power of the laser beam can be adjusted to suit specific metal material, thickness and marking requirements.

Additionally, fiber laser marking machines can create different types of marks, including 2D and 3D barcodes, serial numbers, logos, and even complex graphics. Additionally, fiber laser marking is a fast and efficient process that significantly reduces production time. It can mark large quantities of metal parts in a short amount of time, ensuring businesses achieve optimum productivity and throughput.

Another significant advantage of fiber laser marking on metal is the durability of the marking itself. The laser beam creates a permanent mark that will not fade or wear, ensuring product longevity and traceability. This makes it an ideal solution for industries such as aerospace, automotive and medical devices where permanent marking is critical to safety and compliance.

In the end, fiber laser marking machines are a sustainable and environmentally friendly solution. The marking process does not require any inks, chemicals or other consumables that could be harmful to the environment. Instead, it works by using a beam of light to remove small amounts of the metal surface, leaving a permanent mark.

In conclusion, fiber laser marking machines have revolutionized the way we mark various metal substrates. With their ability to produce high contrast and precise markings, mark different types of metal surfaces and provide durability, speed and sustainability, they are growing in popularity across different industries.

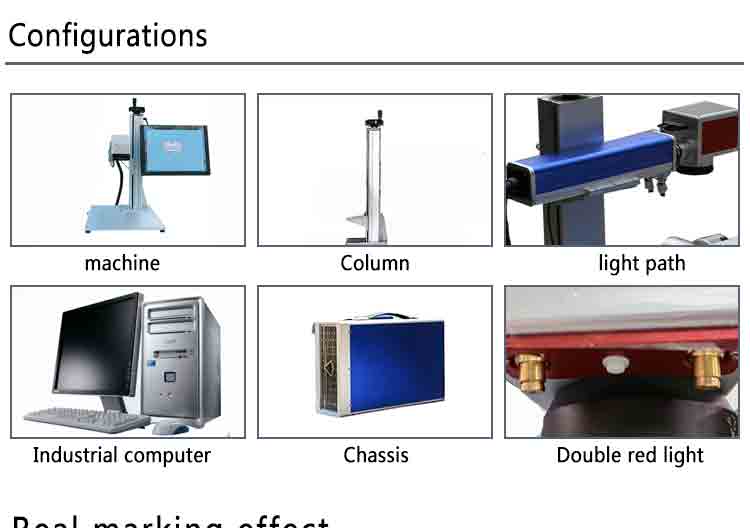

At our company, we are committed to providing our customers with the highest quality laser marking machines designed to increase productivity and efficiency while reducing costs. We offer a variety of models, from handheld portable machines to large industrial machines, so our customers can find the perfect solution for their unique needs.