Laser Engraving, Cleaning, Welding and Marking Machines

Get a quote

Products

20W 30W 50W Fiber Laser Marking Machine For Metal and Bottle

Characteristic ( CHUKE Marking )

● Can process a variety of metal and non-metal materials. In particular, it is more advantageous to mark high hardness, high melting point and brittle materials.

● Non-contact processing, not damage the product, no tool wear, and good marking quality.

● Thin laser beam, small processing material consumption , small processing heat affected zone.

● High processing efficiency, computer control and easy to realize automation.

Specifications

|

Technical Data |

|

|

Laser Type |

Fiber Laser Marking Machine |

|

Laser Power |

20W/30W/50W |

|

Marking Area |

110*110/150*150/200*200/300*300(mm) |

|

Laser Wavelength |

1064nm |

|

Beam Quality |

m²<2 |

|

Marking Speed |

7000mm/s |

|

Marking Depth |

0.01-1mm |

|

Repeated Precision |

±0.002 |

|

Cooling Mode |

Air Cooling |

|

Minimum Line Width |

0.01mm |

|

Working Voltage |

AC220V±10%/50HZ/4A |

|

Application |

Metal And Partial Nonmetal |

|

Optional Parts |

Rotary Device, Lift platform, other customized Automation |

|

Gross Weight |

110KG |

Laser marking machines use laser beams to permanently mark the surface of various substances. The effect of marking is to expose the deep material through the evaporation of the surface material, or to "engrave" traces through the chemical and physical changes of the surface material caused by light energy, or to burn off part of the material through light energy to display the desired etching pattern,word.

Laser marking is widely used in electronic communication components industry, auto parts, mechanical parts, instrumentation, hardware tools, daily necessities, signs and tags industry, packaging bottle cap industry and etc.

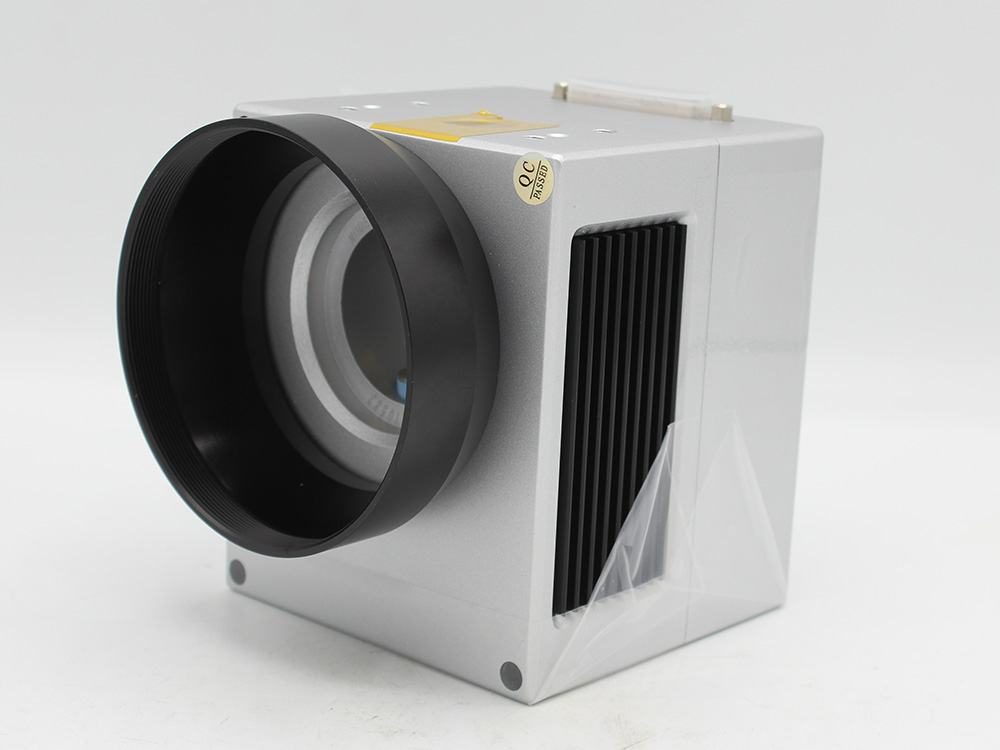

Product Detail Drawing

Application

CHUKE fiber laser marking machine is widely used in integrated circuit chips, computer accessories, industrial bearings, watches and clocks, electronic and communication products, aerospace devices, various auto parts, home appliances, hardware tools, molds, wires and cables, food packaging, jewelry, tobacco As well as the marking of graphics and text in many fields such as military affairs, as well as high-volume production line operations.